Before repairing electrical equipment, it is necessary to know the design of all the most important components. Each driver should know the car starter device, as this is one of the most vulnerable structural elements. The starter is necessary in order to facilitate starting the internal combustion engine. Used on both petrol and diesel engines.

But you can also start the engine with the help of muscle strength, an electric motor, or a pneumatic unit. In passenger cars, the most common way to start the engine is with an electric starter. The battery is used as a power source.

What are starters?

From the total mass of these mechanisms, two large groups can be distinguished: geared and gearless. How the work is done, as well as the internal structure, is clear from the name itself. If there is no gearbox inside the electric motor, then such a starter is capable of developing a small speed. The presence of a planetary gearbox allows you to achieve a higher speed of the rotor. In this case, the electric motor itself may have a relatively small power, but it will be enough to spin the crankshaft of the motor.

But there is one big drawback of such mechanisms - the reliability is extremely low, they can wear out and fail very quickly. But do not think that gearless starters are distinguished by a large resource. They also fail, and even have one significant drawback - with a weak battery charge, they are not able to spin the crankshaft.

The main components of the starter

In fact, the car starter device, the scheme for connecting it to the on-board network, is the same for almost any manufacturer. Regardless of the country in which the car is made and according to what standards. Devices can differ only in the version of execution, the quality of products, but the overall design will be the same. There are several main components:

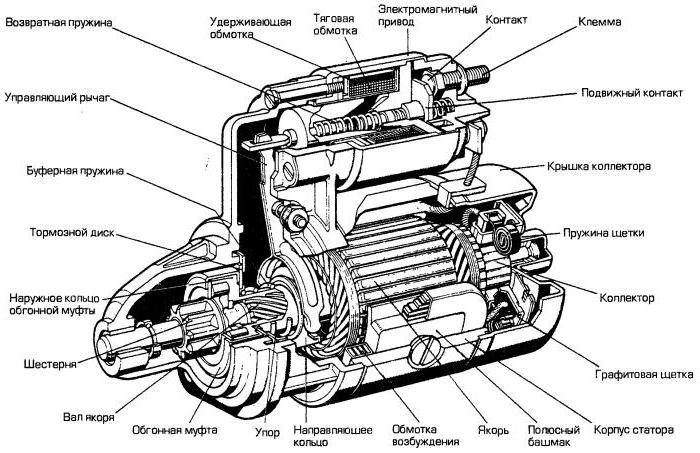

- The rotor is the moving part of the car starter. It has a winding to which an electric current is supplied.

- The stator is a fixed part. Some motor manufacturers install permanent magnets to save money. But it is unreasonable to do this, since the power of the electric motor is significantly reduced.

Typically, this design is used in Without additional gears, the electric motor is not able to develop the torque required to rotate the crankshaft. Such mechanisms have both advantages and rather significant disadvantages. The main plus is that when starting the engine, the starter consumes very little current. But the design of the node is much more complicated.

Bendix and freewheel

These are two components that are mounted on the starter rotor. They are necessary in order to transmit torque from the starter rotor to the flywheel crown. Moreover, the gear, which is located on the overrunning clutch, can only rotate in one direction. Therefore, when diagnosing this mechanism, you just need to try to scroll the gear in both directions.

A solenoid relay is installed in the upper part of the starter housing, which performs the function of a power contact and allows you to move the overrunning clutch with the gear along the rotor axis so that it engages with the flywheel crown. The fork with which the gear moves is made of plastic or metal plates.

How does a starter work?

And now we need to talk about how the car starter rotates the crankshaft. The device, the principle of operation of this mechanism are simple, but there are several nuances that affect the normal functioning. When the key is turned in the ignition lock, voltage is applied to the control contact of the solenoid relay. At the same time, at the retractor, the anchor moves, the bendix gear is engaged with the flywheel.

Also, the solenoid relay closes the power contacts and supplies power to the motor windings. As soon as the key position is changed, power will be cut off from the control output of the traction relay. In this case, the spring, which is located inside the relay, will drop the anchor, and the power contacts will open. At the same time, the bendix will disengage from the flywheel.

Solenoid relay

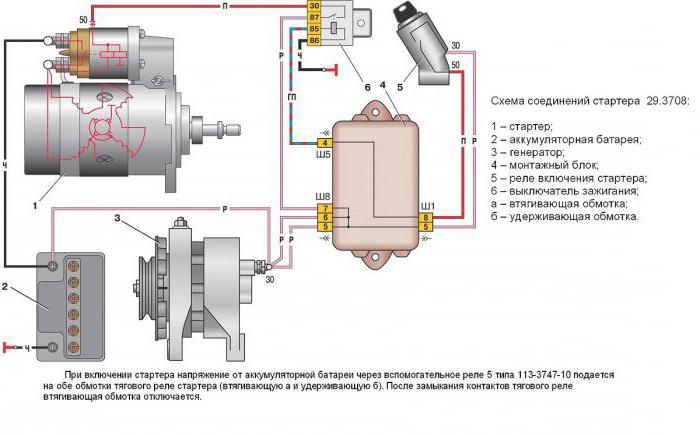

To reduce current consumption, relays are made using a circuit that uses two windings. The first works only at the initial moment of switching on, so that the core of the solenoid relay fully compresses the spring and closes the contacts.

The second winding, made of thin wire, is called the holding winding. Its purpose is to keep the core in a squeezed position. Feature of the winding connection diagram:

- Each coil has two leads. One of them is connected to the control output of the solenoid relay.

- On the holding coil, the second terminal is connected to ground.

The holding coil is connected to ground and a positive terminal. And the current passes through it, but only in the case when the key in the ignition switch is turned to the "Start" extreme position. On the pull-in coil, the second contact is connected to the positive terminal of the vehicle's starter motor. The diagram and views are shown in the figures.

When voltage is applied to the retractor, it, having passed through the stator and rotor coils, is connected to the power minus. In this case, the current will stop flowing through the retracting coil. In this case, only the holding winding will work. With these two windings, a very high pulling force can be achieved, as well as a significant reduction in the current required for holding.

Bushings and brushes

These are two components that greatly affect the normal functioning of the electric motor. Plus power is transmitted through the brushes, and minus passes through the bushings to the rotor winding. When disassembling the starter, special attention must be paid to the condition of these components.

If bushings are worn out, they must be replaced. If the brush assembly is excessively worn, the operation of the starter is undesirable. At the same time, you need to check the condition of the lamellas on the rotor. If necessary, they should be cleaned of dirt. But before starting work, carefully study the car starter device in order to carry out repairs as efficiently as possible.