The principle of operation of the injector is to supply the air-fuel mixture to the combustion chambers in a timely manner. This is necessary for the normal operation of the engine. The control system adjusts the moment the voltage is applied to the electrodes of the candles in order to ignite this mixture. Moreover, these parameters are controlled by a system of sensors installed on the engine.

Electronic control unit

For the operation of any injection motor, a microcontroller-type control unit is required. It connects to:

- Actuating mechanisms by means of electromagnetic relays.

- Sensors through matching devices.

Power is supplied from the onboard network. The principle of operation of the VAZ injector is the same as on any other car. The electronic block consists of:

- Permanent memory - it is necessary for storing information, recording work algorithms.

- RAM - current information is recorded in it, all data is erased from it when the ignition is turned off.

- Microcontroller - it allows you to process incoming signals and regulate the operation of all actuators.

The device memory contains an algorithm of operation, it depends on the incoming signals from the sensors. This algorithm is called "firmware" or "fuel card".

Sensor system

Many sensors are installed on injection engines, they allow you to read the maximum amount of information about the work. The following sensors can be found on domestic and imported vehicles:

- Air consumption.

- antifreeze temperatures.

- crankshaft positions.

- Camshaft positions.

- intake manifold pressure.

- Vehicle speeds.

- The level of gasoline in the tank.

- Throttle positions.

- The concentration of oxygen in the exhaust gases.

All these sensors control the actuators that are involved in the formation of the mixture and the adjustment of the ignition timing.

Mass air flow sensor

This device is based on a thread of precious metal - platinum. The cost of such sensors is very high, so it is better to monitor its condition and prevent damage. Be sure to know what the principle of operation of the sensor is. On VAZs of all models with injection engines, such devices are installed.

It works like this:

- The platinum thread warms up to 600 degrees.

- Through the filter, a stream of air enters the tube with a thread under the action of vacuum in the intake manifold.

- The control unit contains data on the temperature of the thread and the dimensions of the sensor tube.

- The air flow cools the thread by several degrees.

- Based on the temperature difference, the ECU calculates the amount of air that passes through the tube at a certain point in time.

These data are necessary in order to make the fuel mixture in the correct proportion.

Antifreeze temperature sensor

This device allows the electronic control unit to understand that the engine has warmed up to operating temperature. When starting a cold engine in the fuel mixture, it is necessary to reduce the amount of air; for this, the idle speed controller is used. With this, the motor works as efficiently as possible, quickly brought to a stable mode. The principle of operation of HBO 2nd generation on the injector is the same as on the carburetor. That's only with the help of a signal from the temperature sensor, it is possible to realize the start of the engine on gasoline and after warming up the automatic transition to gas fuel. The temperature sensor is located in the engine block or in the thermostat housing.

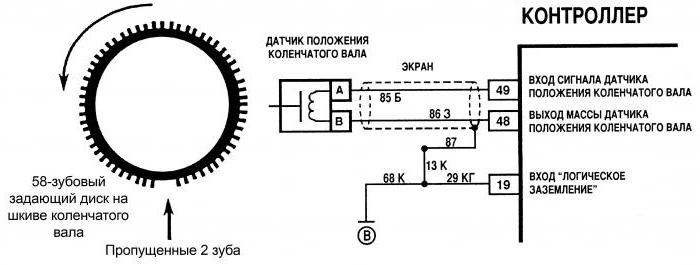

Shaft position sensors

These devices are installed on the crankshaft and camshaft. It is worth noting that sensors are not always used on camshafts - they are often dispensed with. But their use allows you to achieve maximum power from the engine, improve the quality of mixture formation, and correctly adjust the moment the spark is applied to the spark plug electrodes.

The devices work on the Hall effect - when a metal object passes near the active part of the sensor, a pulse is generated. It is fed to the electronic control unit and compared with the rest of the parameters of the motor. The engine can run much better at idle. The principle of operation of the injection system is based on a comparison of the signals from the sensors.

Intake manifold pressure sensor

It is also called the MAP sensor. It can be used both in conjunction with an air flow sensor, and completely replace it. Therefore, if the engine has a MAP sensor, a breakdown of the DMRV is almost not terrible. Its functions will be transferred to this device. At the heart of the element is a sensitive plate, which changes resistance under pressure. The connection with the electronic control unit is made using a matching device.

Throttle position sensor

Mounted on the throttle body, the sensor can be analog or non-contact. The first ones work on the principle of a variable resistor - when the damper axis rotates, the slider moves on the winding. In this case, the resistance of the element changes, the level of the signal entering the electronic control unit decreases or increases. There are non-contact type devices, they work in the same way as encoders. They are highly reliable, but are not interchangeable with analog devices.

The device allows you to evaluate the position of the damper in order to provide information about this to the control unit. The latter, based on this value, will supply exactly as much gasoline to the fuel rail as is necessary for normal mixture formation.

Lambda probe

This is a device that allows you to evaluate the oxygen content in the exhaust system. The sensor is made of ceramic, usually zirconium dioxide. The peculiarity of this material is that it becomes permeable to oxygen ions, provided that it is heated to a temperature of 300 degrees and above. Oxygen levels are measured both inside the exhaust system and outside.

After all, the control unit does not measure the exact amount of oxygen, it only evaluates the difference in the conductivity of the ceramic element inside and outside the system. This is the principle of operation. Injectors on cars function normally only if the system is stable. The sensor outside generates a certain signal, which is considered by the electronic unit as a reference. It is with him that the signal from the internal lambda probe is compared.

Gasoline level sensor

Float-type mechanisms are used, which are very similar in principle to resistive throttle position sensors. When the fuel level in the tank changes, the float will rise or fall. This changes the resistance of the sensor in the circuit. The device is used to notify the driver about the level of gasoline. It can also be used for automatic switching from gas to gasoline and vice versa, if HBO is installed.

Speed sensor

Designed to control vehicle speed. It can be installed both in a cable speedometer and in an electronic one. In the first case, the device only allows you to issue a signal for the operation of the injection system. In the second case, it is included in the electronic speedometer circuit. If there is an electric power steering, an immobilizer or other security systems, this sensor is connected to them. The fact is that the power steering only works when driving at low speed. As soon as the speed increases, the need for an amplifier disappears. Many security systems pair with a speed sensor to ensure maximum security.

Executive mechanisms

Actuators are used for the normal functioning of the injection system. The principle of operation of the Audi mechanical injector is slightly different from the electronic one. The essence of the processes is approximately the same.

The following devices are used in the system:

- Electric fuel pump.

- Idling regulator.

- fuel injectors.

- Throttle node.

- ignition module.

With the help of all these devices, the internal combustion engine is controlled. It is with the help of them that idling can be maintained at a normal level. The principle of operation of the injector in this mode is the same as in any other.

Fuel injection types

Central injection is in many ways similar to a carburetor system, only instead of a complex set of channels and jets, one electromagnetic nozzle is used. It is installed on the intake manifold, and through it the fuel mixture is supplied to the combustion chambers. There is only one drawback - if the nozzle fails, the car will not be able to continue moving.

Systems with twin or phased injection will be much better at work. The latter are especially effective - the mixture enters the combustion chambers of each cylinder, depending on which particular cycle the engine is currently in. One nozzle per cylinder and the same number of ignition coils are installed. But a module can also be used.

Engine gas supply

Injection engines can be easily converted to gas supply (propane or methane). That's only if you decide to install second-generation HBO, you need to use protective measures. The problem is that pops can occur during the operation of gas-balloon equipment. For a carburetor, this is not very scary, but in injection engines, the air flow sensor may fail. The principle of operation of HBO 2nd generation on the injector is to protect the injection system from pops. For this, special devices are installed.

But it is much better to use 4th generation HBO - such devices are designed for installation on injection engines. The kit includes several sensors that complement the standard design, as well as an electronic control unit. It connects to the regular one and takes data on the operation of the engine from it. The fifth generation of gas-balloon equipment is used extremely rarely - its cost is very high.

When switching from petrol to gas, the following conditions must be met:

- In the cooling system, the liquid must be warm - over 50 degrees. Only in this case can the gas evaporate normally in the reducer.

- Be sure to turn off the petrol injectors.

- The gas injectors are switched on immediately.

- Their opening time should be slightly different from the similar parameter of gasoline ones. The coefficient is calculated during calibration.

- There is an adjustment of the ignition timing, since the octane number of the gas is more than 100.

Injector "Venturi" and automobile

They have many differences, but there are also similarities. The principle of operation of the Venturi injector is to pass liquid or gas through a pipe of a certain diameter. This pipe has a nozzle of a certain diameter, through which the substance exits under pressure. With the help of such an injector, it is possible to implement irrigation systems for fields, the supply of liquid to containers in production. In most cases, such injectors measure the amount of liquid passing per unit of time.