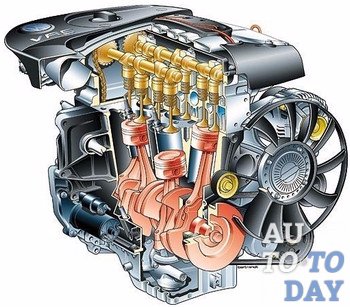

The internal combustion engine, or internal combustion engine, is the most common type of engine found in automobiles. Despite the fact that the internal combustion engine in modern cars consists of many parts, its principle of operation is extremely simple. Let's take a closer look at what an internal combustion engine is and how it functions in a car.

DVS what is it?

An internal combustion engine is a type of heat engine that converts part of the chemical energy obtained from the combustion of fuel into mechanical energy that sets the mechanisms in motion.

Internal combustion engines are divided into categories according to work cycles: two-stroke and four-stroke. They are also distinguished by the method of preparing the fuel-air mixture: with external (injectors and carburetors) and internal (diesel units) mixture formation. Depending on how the energy is converted in the engines, they are divided into piston, jet, turbine and combined.

The main mechanisms of the internal combustion engine

An internal combustion engine is made up of a huge number of elements. But there are basic ones that characterize its performance. Let's look at the structure of the internal combustion engine and its main mechanisms.

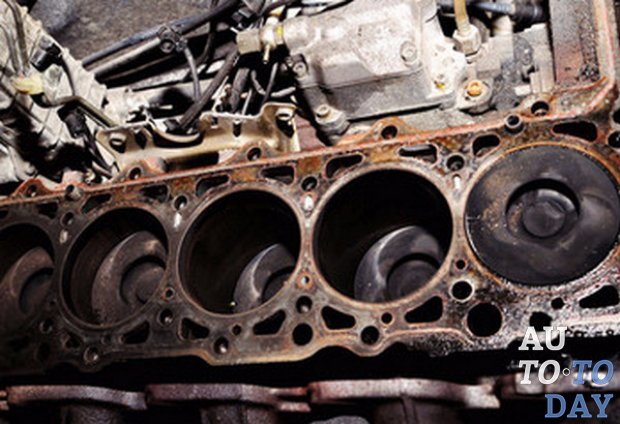

1. The cylinder is the most important part of the power unit. Automotive engines typically have four or more cylinders, up to sixteen in production supercars. The arrangement of cylinders in such engines can be in one of three orders: linear, V-shaped and opposed.

2. The spark plug generates a spark that ignites the air/fuel mixture. Due to this, the combustion process takes place. For the engine to work "like a clock", the spark must be supplied exactly at the right time.

2. The spark plug generates a spark that ignites the air/fuel mixture. Due to this, the combustion process takes place. For the engine to work "like a clock", the spark must be supplied exactly at the right time.

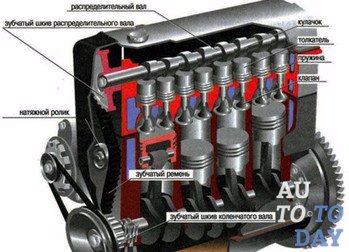

3. The intake and exhaust valves also only function at certain times. One opens when you need to let in the next portion of fuel, the other when you need to release exhaust gases. Both valves are firmly closed when the engine is under compression and combustion strokes. This provides the necessary complete tightness.

4. The piston is a metal part that is shaped like a cylinder. The piston moves up and down inside the cylinder.

5. Piston rings serve as sliding seals for the outer edge of the piston and the inner surface of the cylinder. Their use is due to two purposes:

5. Piston rings serve as sliding seals for the outer edge of the piston and the inner surface of the cylinder. Their use is due to two purposes:

They prevent the combustible mixture from entering the crankcase of the internal combustion engine from the combustion chamber at the moments of compression and the working cycle.

They prevent oil from getting into the combustion chamber from the crankcase, because there it can ignite. Many cars that burn oil are equipped with older engines and their piston rings no longer seal properly.

6. The connecting rod serves as a connecting element between the piston and the crankshaft.

7. The crankshaft converts the translational motion of the pistons into rotational.

8. The crankcase is located around the crankshaft. A certain amount of oil is collected in its lower part (pan).

8. The crankcase is located around the crankshaft. A certain amount of oil is collected in its lower part (pan).

The principle of operation of the internal combustion engine

In the previous sections, we considered the purpose and design of the internal combustion engine. As you already understood, each such engine has pistons and cylinders, inside which thermal energy is converted into mechanical energy. This, in turn, makes the car move. This process repeats itself at an astounding rate of several times per second. Due to this, the crankshaft that comes out of the engine rotates continuously.

Let us consider in more detail the principle of operation of an internal combustion engine. The mixture of fuel and air enters the combustion chamber through the intake valve. Then it is compressed and ignited by a spark from a spark plug. When the fuel burns, a very high temperature is generated in the chamber, which leads to an overpressure in the cylinder. This causes the piston to move towards the "dead center". He thus makes one working move. When the piston moves down, it rotates the crankshaft through the connecting rod. Then, moving from the bottom dead center to the top, it pushes the waste material in the form of gases through the exhaust valve further into the exhaust system of the machine.

Let us consider in more detail the principle of operation of an internal combustion engine. The mixture of fuel and air enters the combustion chamber through the intake valve. Then it is compressed and ignited by a spark from a spark plug. When the fuel burns, a very high temperature is generated in the chamber, which leads to an overpressure in the cylinder. This causes the piston to move towards the "dead center". He thus makes one working move. When the piston moves down, it rotates the crankshaft through the connecting rod. Then, moving from the bottom dead center to the top, it pushes the waste material in the form of gases through the exhaust valve further into the exhaust system of the machine.

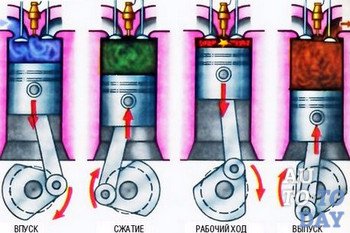

A stroke is a process that occurs in a cylinder in one stroke of the piston. The set of such cycles, which are repeated in strict sequence and for a certain period, is the working cycle of the internal combustion engine.

Inlet

The intake stroke is the first. It starts at the top dead center of the piston. It moves down, sucking a mixture of fuel and air into the cylinder. This stroke occurs when the intake valve is open. By the way, there are engines that have several intake valves. Their technical characteristics significantly affect the power of the internal combustion engine. In some engines, the time the intake valves are open can be adjusted. This is controlled by pressing the gas pedal. Thanks to such a system, the amount of fuel taken in increases, and after its ignition, the power of the power unit also increases significantly. The car in this case can significantly accelerate.

Compression

The second working cycle of an internal combustion engine is compression. When the piston reaches bottom dead center, it rises. Due to this, the mixture that has entered the cylinder is compressed during the first cycle. The fuel-air mixture is compressed to the size of the combustion chamber. This is the same free space between the tops of the cylinder and the piston, which is at its top dead center. The valves are tightly closed during this cycle. The tighter the formed space, the better the compression obtained. It is very important what condition the piston, its rings and cylinder have. If gaps are present somewhere, then there can be no talk of good compression, and, consequently, the power of the power unit will be significantly lower. The amount of compression determines how worn out the power unit is.

The second working cycle of an internal combustion engine is compression. When the piston reaches bottom dead center, it rises. Due to this, the mixture that has entered the cylinder is compressed during the first cycle. The fuel-air mixture is compressed to the size of the combustion chamber. This is the same free space between the tops of the cylinder and the piston, which is at its top dead center. The valves are tightly closed during this cycle. The tighter the formed space, the better the compression obtained. It is very important what condition the piston, its rings and cylinder have. If gaps are present somewhere, then there can be no talk of good compression, and, consequently, the power of the power unit will be significantly lower. The amount of compression determines how worn out the power unit is.

working stroke

This third measure starts at top dead center. And this name he received not by chance. It is during this cycle that the processes that move the car take place in the engine. In this stroke, the ignition system is connected. It is responsible for igniting the air-fuel mixture compressed in the combustion chamber. The principle of operation of the internal combustion engine in this cycle is very simple - the candle of the system gives a spark. After ignition of the fuel, a microexplosion occurs. After that, it sharply increases in volume, forcing the piston to move sharply down. The valves in this stroke are in the closed state, as in the previous one.

Release

The final cycle of the internal combustion engine is exhaust. After the stroke, the piston reaches bottom dead center and then the exhaust valve opens. After that, the piston moves up, and through this valve ejects the exhaust gases from the cylinder. This is the ventilation process. The degree of compression in the combustion chamber, the complete removal of waste materials and the required amount of air-fuel mixture depend on how clearly the valve works.

The final cycle of the internal combustion engine is exhaust. After the stroke, the piston reaches bottom dead center and then the exhaust valve opens. After that, the piston moves up, and through this valve ejects the exhaust gases from the cylinder. This is the ventilation process. The degree of compression in the combustion chamber, the complete removal of waste materials and the required amount of air-fuel mixture depend on how clearly the valve works.

After this step, everything starts anew. What makes the crankshaft rotate? The fact is that not all the energy is spent on the movement of the car. Part of the energy spins the flywheel, which, under the action of inertial forces, spins the crankshaft of the internal combustion engine, moving the piston to non-working cycles.

Do you know? A diesel engine is heavier than a gasoline engine due to the higher mechanical stress. Therefore, constructors use more massive elements. But the resource of such engines is higher than gasoline counterparts. In addition, diesel vehicles ignite much less frequently than gasoline vehicles, since diesel is non-volatile.

Advantages and disadvantages

We have learned what an internal combustion engine is, as well as what its structure and principle of operation are. In conclusion, we will analyze its main advantages and disadvantages.

We have learned what an internal combustion engine is, as well as what its structure and principle of operation are. In conclusion, we will analyze its main advantages and disadvantages.

ICE advantages:

1. The possibility of long-term movement on a full tank.

2. Light weight and tank volume.

3. Autonomy.

4. Versatility.

5. Moderate cost.

6. Compact dimensions.

7. Quick start.

8. Ability to use multiple types of fuel.

ICE Disadvantages:

1. Weak operational efficiency.

2. Strong environmental pollution.

3. Mandatory presence of a gearbox.

4. Lack of energy recovery mode.

5. Works underload most of the time.

6. Very noisy.

7. High speed rotation of the crankshaft.

8. Small resource.

Interesting fact! The smallest engine is designed in Cambridge. Its dimensions are 5 * 15 * 3 mm, and its power is 11.2 watts. The crankshaft speed is 50,000 rpm.

Subscribe to our feeds