It is safe to say that active safety systems have prevented more than tens of thousands of accidents over the years of use in cars, while saving hundreds of lives. One such system is the Anti-lock braking system, or ABS. Consider what ABS is and how the anti-lock braking system of a car works.

purpose

ABS is a system that prevents the vehicle's wheels from locking when braking. Blocking during emergency deceleration is fraught with a number of dangers:

- a car with four locked wheels turns into an unguided projectile sliding along the roadway. The driver loses the ability to control the vehicle, since the locked wheels of the rotary axle are not able to set the direction of movement;

- on a flat, hard surface when the wheels are blocked, the coefficient of adhesion of the tire to the roadway decreases. The result is an increase in stopping distance. It has been experimentally determined that the wheels have the greatest grip with the road at 10-15% slippage. In other words, the car stops most effectively if the wheels are on the verge of locking up;

- under conditions of a difference in the coefficient of adhesion to the roadway, blocking the wheels on one side will lead to a skid of the car. If in your life you have not been in a similar situation, then you could observe such an effect on the training grounds of emergency training courses, when during braking one side of the car is on a hard surface, and the other on a slippery canvas moistened with water. It is difficult even for experienced drivers to react to a car skid in such conditions without proper training.

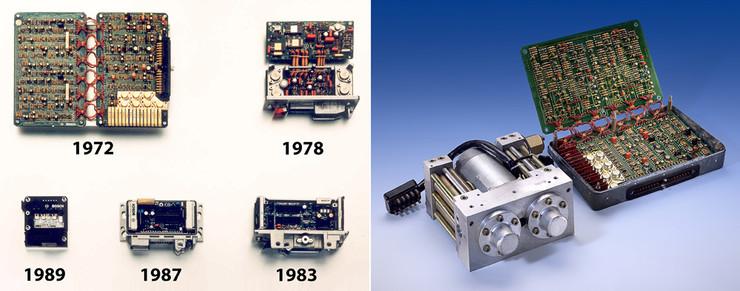

History of development

Despite the fact that as of 2008, about 75% of all new cars were equipped with an assistant, not so much time has passed since the installation of the first serial ABS models on cars. A patent for a system that prevents the wheels from locking was filed by Bosch back in 1936, but the technology was developed only in the 1960s, which was stimulated by the emergence of semiconductor technology. In addition to Bosch specialists, the work on the ABS system was carried out by Teldix, whose chief engineer was Heinz Lieber. In 1970, the Daimler-Benz auto concern, the head of the electrical and electronics department in which the same Heinz Lieber was at that time, announced the creation of the first workable ABS samples. As a regular option, the anti-lock braking system was first installed in 1978 (Mercedes Benz W116 and BMW 7 Series).

Device

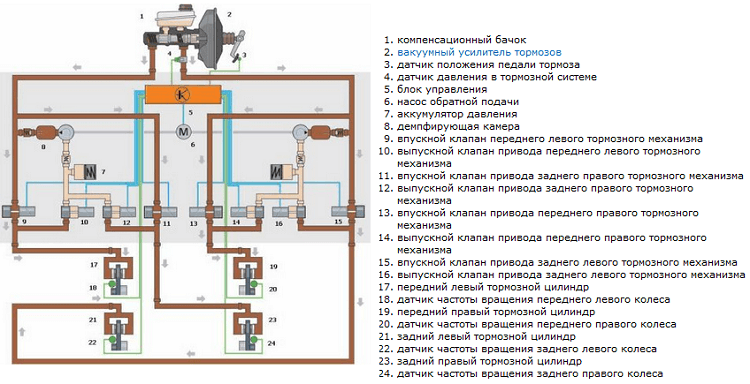

Main components of Anti-lock braking system:

Speed sensors are installed on the hubs of all wheels. Wheel speed measurement is based on the Hall effect. The hydraulic unit has an inlet and outlet valve for each brake channel. The most effective is four-channel ABS (the force of the brake cylinder on each of the wheels is adjusted individually). In many old rear-wheel drive and all-wheel drive cars, a three-channel system was used, in which a common highway was intended for the rear axle wheels. When the pressure in the circuit is released, the brake fluid enters the accumulator. If the volume of the pressure accumulator is not enough to quickly release the pressure in the circuit, the electric hydraulic reverse pump is switched on, which pumps out the brake fluid. Damping chambers are designed to dampen pulsations when pressure is released.

Principle of operation

The ABS starts by receiving information about the wheel speed. The difference in rotational speeds allows the ABS unit to understand which of the wheels is blocked. The hydraulic unit can operate in 3 modes:

- maintaining line pressure. The control unit constantly compares the angular speeds of rotation of the wheels, therefore, if there is a risk of blocking the wheel, the pressure in the corresponding circuit, despite the increase in the force of pressing the brake pedal, will not rise;

- pressure release. The signal transmission from the locked wheel sensor is stopped, so the ABS control unit opens the corresponding exhaust valves (inlet valves are closed). Brake fluid flows into the accumulator, thereby reducing the pressure on the brake pads of the locked wheel. If the battery capacity is insufficient, the forced pumping of the liquid by the reverse electric hydraulic pump begins. At the same time, a characteristic vibration is felt on the brake pedal, which is so familiar to owners of cars with ABS;

- increased pressure on the brake pads. As soon as the wheel starts spinning again and there is no more risk of blockage, the exhaust valve closes and the ABS ECU opens the intake valve. Thus, fluid is again supplied to the brake cylinder under pressure.

The described process of work is cyclical, the modes of operation of the anti-lock braking system change until the car stops completely or stops braking.

Is it all good

The advantages of ABS brakes are more than obvious, but do not forget that the system has several disadvantages:

Despite these serious shortcomings, the total amount of benefit that the anti-lock braking system brings to driving is much more significant. It is ABS that allows you to implement:

- traction control system (ASR);

- downhill assist system (HDC, DAC or DDS);

- lift assist system.

Initially, with the proper skills, the driver could use the intermittent braking technique, thereby simulating the operation of the anti-lock system. At the current stage of ABS development, no driver is able to surpass the efficiency of an electronic system.

The units of a modern anti-lock braking system are quite reliable, so ABS does not cause trouble for owners in operation. But, like any system, the ABS needs maintenance; due to the location in a hostile environment, special attention should be paid to speed sensors and power wires.