Or simply automatic transmissions, appeared in the automotive industry much later than manual transmissions. However, such devices quickly found application on almost all types of road transport and are now used everywhere. One of the elements of an automatic transmission is its torque converter, without which the normal functioning of the entire system would be impossible. Today we will talk about the operating principles of torque converters installed on automatic transmissions and give a comprehensive answer to the question: why is such a design necessary and what roles does it perform on a car?

Purpose

To clearly imagine what role the torque converter plays in an automatic transmission, it is worth remembering the purpose of an ordinary clutch, which is universally installed on manual transmissions.

The clutch acts as a link between the engine and transmission. In other words, if the clutch is not disengaged, then one hundred percent of the motor is transferred to the gearbox, and, consequently, to the wheels. In addition to everything, the manual transmission itself allows the driver to choose the gear himself and change the torque, which allows him to achieve maximum engine efficiency when driving and simply prevent it from stalling in place when the wheels are not rotated.

The main disadvantage of manual transmissions over automatic transmissions is that in addition to constantly selecting the speed manually, you need to depress the clutch pedal. If this is not done, there is a risk of damaging the extremely expensive clutch and burning it, which will lead to the need to replace it.

It was for these purposes that the transformer began to be used. This element is much more complex than the clutch on a manual transmission, which consists of only two disks - a drive and a driven.

But the torque converter allows you to solve the most important and unpleasant feature of “mechanics” in an automatic transmission - the need for constant interaction between the driver and the clutch pedal. So, now you don’t have to depress the pedal when changing gears, and at a traffic light you don’t have to hold it down while the speed is on.

Then the question arises: is it possible to use an ordinary clutch on an automatic transmission instead of a torque converter, as on a manual transmission? The answer is incredibly simple - the automatic transmission itself selects the moment when the gear needs to be changed, and the driver does not know this moment in advance. Consequently, there is no way to press the clutch pedal in time. Hence the need arises to introduce a torque converter into the automatic transmission, which greatly facilitates the interaction between the driver and the box.

Structure

Despite the fact that the torque converter on an automatic transmission has a rather complex operating principle, the general structure of the system is still similar to a mechanical clutch. As far as we know, the clutch consists of two shafts - the drive shaft, which is rigidly connected to the engine, and the driven shaft, which is connected to the transmission.

The torque converter installed on an automatic transmission also has drive and driven elements. But instead of disks rigidly adjacent to each other, these functions are performed by two turbines that rotate opposite each other and do not have a rigid connection.

Here the question arises: on what principle will the two turbines interact with each other? How will they transmit torque among themselves, thus ensuring the vehicle moves in a given mode? It turns out that the connecting role in this system is played not by a rigid element, but by a liquid, which is oil.

Due to its high density, the oil allows you to provide not only constant lubrication, which will protect the metal from wear, but also the transmission of torque due to circulation under high pressure.

However, turbines are not all the elements that are involved in transmitting torque from the engine to an automatic transmission. Another small turbine, called a reactor, is installed between the driving and driven elements. Its purpose is to transform the transmitted energy, change the torque and force transmitted from the engine to the box. It is worth noting that, unlike turbines, the reactor does not always rotate. Its operation is necessary only at those moments when the wheels need to transmit torque other than the nominal one.

Functional scheme

The driving turbine is called a pump wheel and is rigidly connected to the engine flywheel. This means that its rotation speed can be changed by interacting with the accelerator pedal.

The leading turbine does not have its own name. It, unlike the pump, is connected to and, thus, interacts with it. The reactor is located between the turbines and is rotated only from time to time.

The turbines and reactor have a system of oil channels. This allows the oil to circulate along a strictly defined path, so there is minimal wear on metal parts and maximum efficiency is achieved.

When the car is stationary, it is necessary that the driven turbine remains stationary. This is necessary so that the car does not simply stall, and its engine does not stop working when idling.

In this mode, the effect of a depressed clutch pedal is simulated - the oil pressure is minimal, and therefore the turbines do not have any indirect interaction.

As soon as the car begins to move, the number of revolutions of the pump increases, and therefore the oil pressure increases. Due to this, the driven turbine begins to rotate with a given force, and the wheels begin to move. When certain speeds are reached, the reactor is activated. It changes the pressure in such a way as to prevent the car from stalling and prevent the driver from feeling power failures.

Summary

A torque converter is one of the most important components of any modern “automatic machine”, ensuring its proper operation. This device provides automated control of torque when transmitting it from the engine to the wheels. This allows us to judge that in case of sudden drops in power and torque, it is worth paying attention to the condition of this particular unit and performing its high-quality diagnostics.

As technology developed, the design became more complex and modernized. Currently, the transformer on an automatic transmission serves as the clutch. That is, during transmission adventures, this element opens the connection between the box and the engine. Immediately after upshifting or downshifting, the torque converter absorbs part of the torque, which allows for the smoothest gear shifting.

Working principle | General information | Device |

The design of the torque converter for an automatic transmission consists of three rings with blades. All three rings rotate accordingly and are located in one housing. Inside the housing there is a working fluid that allows you to lubricate and cool the moving elements. The torque converter is mounted on the crankshaft and then connected directly to the gearbox. The working fluid is pumped into the device body using a special pump. The pump allows you to provide the necessary pressure, and if there are problems with the tightness of the structure, active leaks of working fluid appear, which in turn leads to damage to the mechanical rotating elements.

Modern torque converters, which are used on, are fully computer controlled, and numerous sensors monitor the pressure and speed of the shafts inside the transformer core. It must be said that such a complication of the design led to a decrease in the reliability of the device and torque converter device generally. In particular, the service life and reliability indicators are affected by operation in the most severe conditions, which is typical for modern cars.

Torque converter operation Video

The operation of the torque converter is monitored and optimized using a special control unit. This fully automatic control system receives data from numerous sensors installed in the box and the torque converter itself. If any problems arise in the operation of the device, the automation displays an error message. In some cases, the operation of the torque converter may be completely blocked, which leads to the engine shutting down when the operating modes of the box change. It should also be noted that most transformer failures occur at the mechanical level. Therefore, when diagnosing a car, it is difficult to accurately determine the nature and location of the breakdown. It is necessary to disassemble the damaged element and visually inspect it. This is the only way to determine the existing breakdown.

Engineers from leading car manufacturers are constantly conducting research that should improve the reliability of equipment and eliminate problems in the operation of this device. The emergence of new design developments makes it possible to significantly modernize the torque converter, which today can be easily used on cars equipped with diesel engines. Such diesel engines are characterized by high torque. If previously transmissions had difficulty coping with high torque levels and quickly failed, today the reliability of automatic transmissions and torque converters has significantly increased.

Torque converter automatic transmission device

Theoretically, the service life of the torque converter coincides with. However, like any other mechanical element, it can fail and require repair. In some cases, it is necessary to completely replace the torque converter, which leads to significant expenses for the car owner. torque converter repair.

Automatic transmission torque converterSymptoms of a problem

We will describe the main symptoms of torque converter breakdowns, which should be a reason for prompt contact to specialized repair shops.

1 A slight mechanical sound may be heard when changing gears. As the speed increases and under load, the mechanical sound disappears. This may indicate problems with the support bearings. It is necessary to disassemble the torque converter and evaluate the condition of the bearings.

2 In the speed range from 60 to 90 kilometers per hour, slight vibration may be observed. As torque converter problems worsen, the vibration will increase. This may be caused by the fact that wear products from the working fluid can clog the oil filter. In this case torque converter repair consists of replacing the oil filter and torque converter fluid. As a rule, it is necessary to simultaneously change the oil in the engine itself and the gearbox.

3 The presence of problems with the dynamics of the car indicates a failure of the so-called overrunning clutch. In this case, it is necessary to disassemble the torque converter and replace the failed clutch.

4 Stopping the car without being able to continue driving indicates damage to the spline on the turbine wheel. Torque converter repair consists of installing new splines or replacing the entire turbine wheel.

5 The appearance of a characteristic rustling noise when the car is running indicates problems with the bearing, which are located between the turbine or reactor wheel and the torque converter cover. When moving, this rustling sound may disappear completely. In this case, you need to contact the service center as soon as possible and carry out repair work. In most cases, damaged needle thrust bearings will need to be replaced. The cost of such repairs is not too high.

6 A loud metallic noise may be heard when shifting gears. This indicates deformation and prolapse of the shoulder blades. The repair consists of replacing the damaged wheel in the torque converter.

7 It is necessary to regularly check the condition of the oil in the torque converter and gearbox. If aluminum powder appears on the gearbox oil dipstick, it is necessary to check the freewheel, which is made of an aluminum alloy. In most cases, the appearance of such powder on the dipstick indicates torque converter malfunction and wear of the end washer.

8 When the vehicle is running and stationary, a characteristic smell of melting plastic may appear in the area of the gearbox. This happens due to overheating of the torque converter and melting of the polymer elements and parts of this device. Overheating of the torque converter can occur for several reasons. First of all, these are problems with lubrication. For example, when the oil level drops, characteristic signs starvation of the box and torque converter. There may also be problems with the system, which cannot effectively cool the oil in a clogged heat exchanger. Repair in this case consists of changing the oil and checking the functionality of the lubricant cooling system.

9 When changing gears or when changing gearbox operating modes, the engine may stall. This indicates a failure of the control automation, which blocks the operation of the torque converter. The repair consists of replacing the failed control unit.

It should be noted that there are no specific signs of torque converter malfunction. Therefore, in some cases, service center specialists cannot immediately determine signs and the nature of the failure. All this leads to increased repair costs and constant vehicle downtime for service.

Torque converter repair

Despite the apparent complexity, repairing a torque converter is not particularly difficult and can be done by the car owner himself. The only caveat is to remove the torque converter from the gearbox. In this case, it is necessary to use a special repair kit that will allow dismantling work. When carrying out repair work, the body of the device is cut, after which the condition of the torque converter is checked. That is why during repair work it is necessary to replace not only the sealing rings, but also the device body itself. During repair work, the oil seal and sealing rings are replaced. It is prohibited to use old, even well-preserved, rings and seals. In some cases, it is possible to weld the torque converter housing, which makes it possible to achieve complete tightness of the device. After completing the work, you need to install the repaired device on the gearbox and carry out balancing work.

It should be noted that in case of certain types of torque converter breakdowns, its repair and replacement of failed elements is not practical from an economic point of view. It is much easier to purchase new devices and install it in place of the damaged element.

Torque converter repair Video

As you can see, repairing a torque converter is relatively simple. However, without appropriate training and experience in car repair, it is not possible to carry out it yourself. Therefore, if you doubt your abilities, it is best to turn to professional specialists. The cost of a new torque converter can be about a thousand dollars, depending on the make of the car.

If you switched from a manual to an automatic, then...

If you switched from “mechanics” to “automatic”, then at first pay close attention to “taming” your left leg.

The fact is that when driving a car with an automatic transmission, the left leg is not used (resting). And the acquired habit of squeezing the clutch pedal when braking will be a great hindrance.

Drivers who switched from a manual transmission to an automatic transmission all tell stories about how sometimes in a critical situation they pressed the clutch pedal, which is absent on an automatic transmission.

The result is obvious - instead of the clutch, the brake pedal was placed under the left foot, which was automatically pressed all the way. The car was stuck in a jam, and at best only the passengers stared at the driver in bewilderment.

This experience also affected me, but, fortunately, there were no negative consequences. At first I had to hide my left leg under the driver's seat. Over time, to my surprise, alternating between driving a manual and an automatic transmission did not cause any difficulties.

Therefore, first it would be a good idea to familiarize yourself with the “automatic” on a safe section of the road. And how to practice sharp movements of the right foot from the “gas” to the “brake” without squeezing the missing clutch.

Hide...

Acquaintance

On a car with an automatic transmission, there is a lever with a button at the location of the gear shift lever. It would be more correct to call it selector for selecting automatic transmission operating modes.

There are also gears in the automatic transmission, but when driving they are switched not by the driver, but in automatic mode. As a rule, a classic automatic transmission has 4 gears (but now you can increasingly find 5 and even 6-speed ones). The gear shift moment can usually be felt during heavy acceleration.

Basic operating modes of automatic transmission

First, let's look at what operating modes are offered to the driver by such a “smart” box.

Mode "P" - Parking, blocks the drive wheels. This selector position is equivalent to pulling the handbrake. As you can guess from the name, it is used when parking. In this mode we start and stop the engine.

Move the selector to position "R" on a moving car is equivalent to putting a stick in the wheel. Such an error will lead to costly automatic transmission failure.

Mode "R"- Reverse. As you might guess, this mode includes reverse gear.

Enable mode "R" It is also necessary at a time when the car has completely stopped and is not moving forward.

"N" - Neutral. This is the next mode after "Reversa", is equivalent to neutral gear on a conventional gearbox. "Neutral"- i.e. nothing is turned on, while the wheels are not connected to the engine and rotate freely.

If you decide to push or tow a car, then of course you should turn on this particular mode.

Mode "D"- Drive (movement). The most favorite mode for any owner of a car with automatic transmission. Of course, this mode will allow us to move forward. Moreover, depending on the degree of pressing of the gas pedal* and driving conditions, gears in this mode will be switched automatically, i.e. for you. And when the speed decreases, the “smart” gearbox will apply engine braking itself.

Another obvious advantage of the mode "D" - this means that when starting to move uphill, the car will not roll back. What could be better! But don’t delude yourself too much - if the slope is steep, the car can still slowly roll back.

* - the gas pedal is more correctly called the fuel control pedal or the accelerator pedal, or even the throttle control pedal. In the technical literature, it is the last two options that are most often found.We looked at the selector positions that are most often used during normal driving. Almost always, cars with automatic transmission have and, which are used much less frequently. About them below.

What, how and when to turn on?

You can move the selector knob to the appropriate mode only after:

- press the brake pedal.

- press the button on the selector lever handle*,(it is located on the side or front, and sometimes on top).

Oh yes, you can only move the lever with the car running (with the ignition key turned). And the habit of pressing the brake pedal before starting the engine will never be superfluous.

Those. Before you start moving you need to:

1. With the engine running, press the brake pedal;

2. Press the button on the selector lever handle;

3. Set the selector to the appropriate mode.

Before turning on "Drive" you have to jump through two positions "R" And "N". But since we don’t need them at the moment, we shouldn’t dwell on them.

The required gear in the box itself is switched on a second (two) after you have set the desired mode. At this moment, the engine speed drops slightly (the sound of the engine becomes duller).

* - The selector lever switches to some positions without additional pressing of the brake and button. These modes can be activated on the go. We will also mention them.Driving in the selected mode

Now comes the fun part.

After engaging the gear, the car will not move immediately. You keep the brake pedal pressed. But as soon as you release it, the car will immediately start moving!

If you start moving uphill, the car will only move when you add engine speed. Which is extremely inconvenient when you need to slightly move the car up a slope. In this case, you will have to press on the gas pedal and then quickly press on the brake. The main thing here is not to overdo it with gas!

In mode "D" the car will move forward slowly. In mode "R"- back. On "Neutrals" the car will stand still or roll down the slope of the road! This must be taken into account and not release the brake ahead of time.

Those. in modes "D" And "R" the motor constantly pushes the car, even if the gas pedal is released.

When driving, the automatic transmission recognizes the driver’s commands precisely by moving the gas pedal. Smooth presses will lead to smooth acceleration and leisurely gear changes.

But if you need intense acceleration, for example, when overtaking, do not be afraid to press the gas all the way to the floor. For an automatic transmission, this is a command for maximum acceleration. In this case, the box will first switch to a lower gear (the so-called kick-down mode). And only after this the car will begin to really accelerate.

One of the disadvantages of a classic automatic transmission is about a second delay between the moment you press the gas pedal and the actual acceleration. This is quite a bit when driving slowly, but when overtaking, when sometimes every moment is precious, this time must be taken into account.

Stop

If you decide to stop, then with an automatic transmission everything is simple: press the brake pedal and stop in the right place. In this case, there is no need to move the shift lever while driving.

If the stop is short, for example, in front of a traffic light, then the selector lever from the mode "D" It's better not to translate. You don’t want to wear out the mechanisms of your favorite automatic transmission unnecessarily.

You will have to keep the brake pedal depressed after stopping.

In traffic jams and during long stops (more than half a minute), try to give the engine a break and not burn gasoline in vain. Otherwise the engine is in mode "Drive" It will take too long to unnecessarily push the braked car, and this, of course, will consume some of the fuel.

In such cases, you can enable the mode "N"*, (it is advisable not to release the brake pedal). Or turn on the mode "P", which will stop the wheels and allow your right leg to rest (let me remind you that in this mode the car will not even roll downhill).

From mode "D" on "N" and back, the selector lever jumps itself without additional presses, which is very convenient, for example, when driving in a traffic jam, where frequent short stops are necessary.

Warnings!

- When driving a car with an automatic transmission, only the right foot is used, which controls two pedals - “brake” and “gas”. The left leg is not involved in steering at all.

- If the selector lever is not in position "R", get into the habit of keeping the brake pedal depressed, especially if the car is parked on a slope, (even if at the same time "Drive" your car does not roll backwards).

- Do not turn on the mode "N" while moving!

I would like to warn against turning on "Neutrals" when the car is moving, especially if you are rolling down a hill and at the same time slowing down with the brake pedal. You won't be able to save a lot of fuel, but the brake pads will heat up more. Do not forget that when the vehicle speed decreases in "Drive" The automatic transmission additionally includes engine braking.If you still want to coast, then from the mode "D" on "N" move the lever without pressing the selector knob button. Immediately before braking, return to "D" again without pressing a button. This will prevent erroneous activation "Reversa" or "Parking" and stop the car more efficiently.

Almost always on cars with automatic transmission there is a button for an additional mode of operation of the box. We will limit ourselves to the description Winter mode, because it occurs most often.

Winter mode has different designations: "*", "HOLD", "W", "WINTER", "SNOW".

The goal of the winter program is to eliminate wheel slipping when starting to move and when changing gears.

To do this, the operation of 1st gear is excluded altogether. The car starts moving immediately from speed 2. Subsequent gears are engaged at lower engine speeds, which allows for smaller acceleration differences and reduces the likelihood of skidding.

In summer, it is highly not recommended to use winter mode on roads with good coverage. In this mode, the automatic transmission works with more load and heats up more than usual.

Additional selector positions. Sub-modes "D"

Depending on the modification, automatic transmissions almost always have additional selector positions:

Automatic transmission modes that limit gear shifts.

"3" or "S"- In this mode, the automatic transmission will not shift above 3rd gear. This selector position is usually used for non-standard driving conditions, for example, on moderate climbs or descents, etc.

I sometimes use this mode outside the city at high speeds when I need to quickly overtake in a loaded vehicle. Mode "Drive" in such situations it gives rather sluggish acceleration. In mode "3" overtaking occurs at high engine speeds and no time is wasted on changing the next 4th gear. (At higher speeds, the engine develops more power and accelerates the car better).

Those. for example, you were following a truck at a speed of 70-80 km/h at "Drive" and then you have the opportunity to overtake him. Move the selector lever to mode "3", squeeze the gas and start overtaking. After completing the maneuver, without pressing the button, move the lever back to the position "D".

And sometimes there are situations when you were moving in fourth gear in "D" and also decided to overtake. You press the gas, the automatic transmission switches to a lower gear (kick-down mode). But for some reason you changed your mind about overtaking and slightly loosened the pedal, the automatic transmission goes back to fourth. But now the opportunity to make a maneuver has arisen again, and you squeeze the gas again. The automatic transmission engages third again, which wastes precious time.

In such a situation, it is also preferable to move the selector to "3". This will prevent the automatic transmission from changing gears inappropriately and will reduce overtaking time.

What speed can you accelerate to in “3” mode?

The speed limit of 3rd gear depends on the car, but a speed of 130-140 km/h is usually not the limit for it. The tachometer needle will tell you everything, the main thing is not to let it go into the red zone.

"2"- In this mode, the automatic transmission does not shift above 2nd gear. The speed limit of this mode is approximately 70-80 km/h. Typically used on fairly steep slopes and slippery surfaces.

"L" or "1"- Mode for severe driving conditions: very steep slopes, off-road, etc. The transmission will only operate in the lowest gear. Above 30-40 km/h at "L"(Low) It's better not to speed up.

Attention! Accidentally engaging the “L” or “2” mode at high speed will cause the vehicle to suddenly slow down, which can lead to skidding.

All of the above modes can be used not only on climbs, but also on descents, where intense engine braking is required.

Hide...

To describe the operating modes, click on the corresponding figure of the automatic transmission type.

Many automatic transmissions, in addition to the main selector positions, may have a groove for the so-called manual gear shift mode. Such boxes are called selective (car manufacturers give them different names: “Tiptronic”, “Steptronic”, etc.).

“M” - Manual mode selective automatic transmission

To switch to manual mode, simply move the selector to the position provided for this "M" to the left or to the right "Drive". This mode can be turned on even on the go, which will lead to fixation of the engaged gear.

Move the selector up to the position «+» , you change the gear to a higher gear, and by moving the selector down «-» one step lower. At the same time, you don’t have to release the gas pedal.

Usually, an automatic automatic transmission, even in manual mode, protects the driver from erroneous activations and does not allow the box to operate in extreme modes. Those. pregnant "M" Sometimes gears may either not engage or shift on their own, for example, when the car slows down.

This mode is used quite rarely, for example, when overtaking or when driving on difficult road sections: slippery surfaces, deep snow, steep climbs, descents, etc.

Hide...

What doesn't automatic transmission like?

1. An unheated automatic transmission does not like loads and high speeds.

Even if it’s summer outside, for the first few kilometers (or at least 5-10 minutes), try to move at low speed, without sudden acceleration. Wait until the oil in the engine and gearbox warms up to an acceptable temperature. Do not forget that the box warms up much slower than the engine.

And in winter, before starting to drive, you can additionally drive the oil in the box by alternately moving the selector handle to different modes, holding the lever on each of them. You can even stand for a little while in the driving mode. The brake pedal must, of course, be pressed.

Also, in the cold season, to warm up the automatic transmission faster, you can drive for the first few minutes with the winter mode button on.

2. Avoid off-road driving.

Cars in general, and automatic transmissions especially, do not like wheel slip. For this reason, avoid sudden pressure on the gas pedal on surfaces with uneven coverage.

If your car is stuck, don’t even think about trying to drive out. "Drive"! For this there is "L" or "1" broadcast. But first, if possible, without allowing the wheels to slip, try to drive back along your own track.

Driving off-road is a different story, but it’s better to once again work with a shovel, jack up the car or involve someone than to press on the gas and hope for a miracle.

4. Do not tow heavy trailers with a car with automatic transmission!

Due to the peculiarities of the device, the automatic transmission categorically does not like heavy loads (the gearbox begins to overheat and wear out excessively). Therefore, it is better to entrust towing another car or a heavy trailer to a mechanical fellow.

3. Do not tow a faulty car with an automatic transmission!

If possible, do not carry an automatic rifle on a “tie”, in the sense of in tow. But if there are no other options, then once again take a look at the operating instructions for your automatic transmission.

Most likely there will be strict restrictions. Towing an automatic transmission is usually allowed at a speed of no more than 30-50 km/h and for a distance of no more than 30-50 km (to avoid overheating).

It is advisable to tow an automatic with the engine running, because... in this case, normal lubrication of the gearbox mechanisms will occur.

Attention: some cars with automatic transmission cannot be towed at all!

Why does a car with automatic transmission need a handbrake?

My observations have shown that owners of automatic vehicles practically do not use the parking brake on their cars. When parking, use the mode "Parking", during short stops - the brake pedal.

But if you look at the rules for operating a car with an automatic transmission, you will see something like the following: “Always use the parking brake. Do not rely on moving the selector lever to the P position to prevent the vehicle from moving.”

For what reason does the manufacturer not trust "Parking" I honestly don't know. Personally, this mode has never let me down and always faithfully fixed the car even on steep slopes without using the handbrake.

And the forgotten handbrake, there were times when it failed. For example, I really remember the case when in winter I could not move the car due to frozen brake pads. (In winter, such tricks sometimes happen after washing a car or driving through deep puddles).

A friend of mine had the same problem in the summer due to “rusted” brake discs, when he left his car with the handbrake on while on vacation.

For this reason, when parking for a long time on a steep slope, it is preferable not to use the handbrake, but to place something under the wheels, or rest them against a curb stone located on the side, after first turning the steering wheel in the right direction.

Without a doubt, the handbrake can and should be used in the following cases:

- additional securing of the car when stopping with the engine running, especially if you decide to leave the cabin.

- for reliable braking of the car, for example, when changing a wheel, and in other similar situations.

- It is also advisable to tighten the handbrake when stopping on a steep slope, before setting the mode "P". It’s just different that on steep slopes the selector with "Parking" moves (pulls out) with excessive force*.

In such situations, before starting to drive, do not forget to first remove the selector lever from "Parking" and only then release the handbrake.

And don't forget to remove the parking brake before driving!**

* - Mode lock on slopes "Parking", which stops the drive wheels, is loaded much more heavily.

** - Drivers of automatic vehicles usually do not have the habit of checking the removed handbrake before starting off. Having used the handbrake for some reason, some people completely forget about it. The red light on the instrument panel is sometimes noticed quite late.

Three disadvantages of a classic automatic transmission

1. We have already talked about the “thoughtfulness” of the automatic transmission when sharply pressing the gas.

2. The next big disadvantage of the classic “automatic” is the loss in acceleration dynamics and in comparison with mechanics. And this difference is especially evident during acceleration. The more intense it is, the more fuel the automatic transmission will consume compared to a manual transmission. In suburban driving mode, as a rule, the appetite of both cars is almost identical.

I think it is unnecessary to remind you of the preference for smooth accelerations and smooth decelerations.

3. I think everyone has heard about the exorbitant cost of a new automatic transmission and repairing a faulty one. But we must pay tribute to the manufacturers of such complex units - breakdowns of “machines” during CORRECT OPERATION are very rare.

Automatic and manual transmission, who will win?

Progress does not stand still, and automatic transmissions are increasingly appearing, devoid of many of the disadvantages of their older brothers. Such types of gearboxes as “variator” and “robotic gearbox” have become widespread.

Some of them managed not only to beat the “mechanics” in acceleration time, but at the same time even reduce fuel consumption.

Without going into details, I will only say that any checkpoint has both its pros and cons. Today everyone can choose exactly what suits them best.

But the trend is obvious: the “automatic” is increasingly replacing the classic “mechanics”.

Note: in this article we looked at control techniques for a classic automatic transmission. The operating modes of the robotic gearbox and variator are very similar to those described above, with the exception of various nuances associated with the design of these units.

With the development of the automotive industry and the release of new types of transmissions, the question of which gearbox is better is becoming increasingly relevant. Automatic transmission - what is it? In this article, we will understand the structure and operating principle of an automatic transmission, find out what types of automatic transmissions exist and who invented the automatic transmission. Let's analyze the advantages and disadvantages of different types of automatic transmissions. Let's get acquainted with the operating and control modes of the automatic transmission.

What is automatic transmission and the history of its creation

Automatic transmission selectorAn automatic transmission, or automatic transmission, is a transmission that selects the optimal gear ratio according to driving conditions without driver intervention. This ensures a good smooth ride of the car, as well as driving comfort for the driver.

Currently, there are several types of automatic transmission:

- hydromechanical (classical);

- mechanical;

In this article, all attention will be paid to the classic slot machine.

History of invention

The basis of the automatic transmission is a planetary gearbox and a torque converter, first invented exclusively for the needs of shipbuilding in 1902 by the German engineer Hermann Fittenger. Then, in 1904, the Startevent brothers from Boston presented their version of an automatic transmission, which had two gearboxes and resembled a slightly modified mechanics.

First production GM Hydramatic automatic transmission

First production GM Hydramatic automatic transmission A car equipped with a planetary gearbox first saw the light of day under the Ford T brand. The essence of the box was smooth gear shifting using two pedals. The first included upshifts and downshifts, and the second included reverse gears.

The baton was taken up by General Motors, which released a semi-automatic transmission in the mid-1930s. The clutch was still present in the car, and the planetary mechanism was controlled by hydraulics.

Around the same time, Chrysler refined the design of the gearbox with a fluid coupling, and instead of a two-stage gearbox, overdrive was used - an overdrive gear with a gear ratio of less than one.

The world's first fully automatic transmission was created in 1940 by the same company, General Motors. The automatic transmission was a combination of a fluid coupling with a four-speed planetary gearbox with automatic hydraulic control.

Today, six-, seven-, eight- and nine-speed automatic transmissions are already known, the manufacturers of which are both automakers (KIA, Hyundai, BMW, VAG) and specialized companies (ZF, Aisin, Jatco).

Pros and cons of automatic transmission

Like any transmission, automatic transmission has both pros and cons. Let's present them in the form of a table.

Automatic transmission device

Automatic transmission diagram

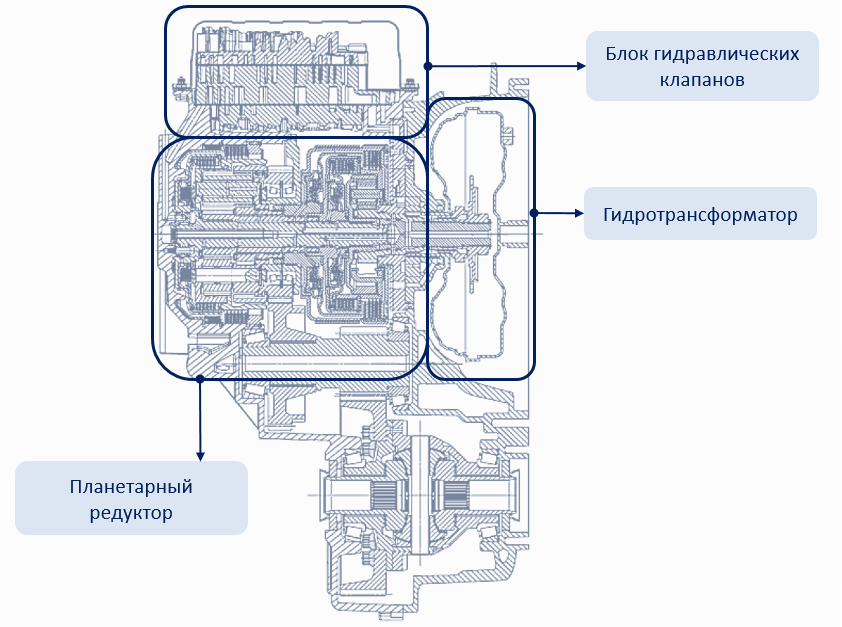

Automatic transmission diagram The automatic transmission device is quite complex and consists of the following main elements:

- planetary mechanism;

- automatic transmission control unit (TCU);

- hydraulic unit;

- band brake;

- oil pump;

- frame.

The torque converter is a housing filled with a special ATF working fluid and is designed to transmit torque from the engine to the gearbox. In fact, it replaces the clutch. It consists of pump, turbine and reactor wheels, a locking clutch and a freewheel.

The wheels are equipped with blades with channels for the passage of working fluid. A lock-up clutch is necessary to lock the torque converter in specific vehicle operating modes. A freewheel (overrunning clutch) is necessary to rotate the reactor wheel in the opposite direction. You can read more about the torque converter.

The planetary mechanism of the automatic transmission includes planetary gears, shafts, drums with friction clutches, as well as an overrunning clutch and a band brake.

The gear shift mechanism in an automatic transmission is quite complex, and, in fact, the operation of the transmission consists of executing some algorithm for turning the clutches and brakes on and off using fluid pressure.

The planetary gear, or more precisely the locking of one of its elements (sun gear, satellites, ring gear, carrier), ensures the transmission of rotation and changes in torque. The elements included in the planetary gear set are locked using an overrunning clutch, a band brake and friction clutches.

An example of an automatic transmission hydraulic diagram

An example of an automatic transmission hydraulic diagram The automatic transmission control unit can be hydraulic (no longer used) and electronic (automatic transmission control unit). Modern hydromechanical transmission is equipped only with an electronic control unit. It processes sensor signals and generates control signals to the actuators (valves) of the valve body, which ensure the operation of friction clutches, as well as control the flow of working fluid. Depending on this, fluid under pressure is directed to one or another clutch, including a specific gear. The TCU also controls the torque converter lock-up. In the event of a malfunction, the TCU ensures that the gearbox operates in “emergency mode”. The automatic transmission selector is responsible for switching gearbox operating modes.

The following sensors are used in the automatic transmission:

- input speed sensor;

- output speed sensor;

- automatic transmission oil temperature sensor;

- selector lever position sensor;

- oil pressure sensor.

Operating principle and service life of automatic transmission

The time required to change speed in an automatic transmission depends on the speed of the vehicle and the load on the engine. The control system calculates the required actions and transmits them in the form of hydraulic influences. Hydraulics move the clutches and brakes of the planetary mechanism, thereby automatically changing the gear ratio in accordance with the optimal engine mode under given conditions.

One of the main indicators affecting the efficiency of an automatic transmission is the oil level, which must be checked regularly. The operating temperature of the oil (ATF) is about 80 degrees. Therefore, in order to avoid damage to the plastic mechanisms of the box in winter, the car must be warmed up before driving. And in the hot season, on the contrary, cool it.

The automatic transmission can be cooled by coolant or air (using an oil cooler).

The most common type is the liquid radiator. The atf temperature required for normal engine operation should not exceed 20% of the cooling system temperature. The coolant temperature should not exceed 80 degrees, due to this the atf is cooled. The heat exchanger is connected to the outer part of the oil pump housing, to which the filter is attached. As oil circulates in the filter, it comes into contact with the cooling liquid through the thin walls of the channels.

By the way, automatic transmission is considered very heavy. The weight of the automatic transmission is about 70 kg (if it is dry and without a torque converter) and about 110 kg (if it is filled).

For the automatic transmission to function properly, correct oil pressure is also necessary. The service life of the automatic transmission largely depends on this. The oil pressure should be between 2.5-4.5 bar.

The resource of an automatic transmission may vary. If in one car the transmission can last only 100 thousand km, then in another it can last about 500 thousand. This depends on the operation of the car, on regular monitoring of the oil level and its replacement along with the filter. It is also possible to extend the life of an automatic transmission by using original consumables and timely servicing of the transmission.

Automatic transmission control

The automatic transmission is controlled by the automatic transmission selector. The operating modes of the automatic transmission depend on moving the lever to a certain position. The following modes are available in the machine:

- R - Parking. Used when parking. In this mode, the transmission output shaft is mechanically blocked.

- R - Reverse. Used to engage reverse gear.

- N - Neutral. Neutral mode.

- D – Drive. Moving forward in automatic gear shift mode.

- M - Manual. Manual gear shift mode.

In modern automatic transmissions with a large number of operating ranges, additional operating modes can be used:

- (D), or O/D-overdrive - “economical” driving mode, in which automatic switching to an overdrive is possible;

- D3, or O/D OFF - stands for “disabling overdrive”, this is the active driving mode;

- S(or number 2 ) - range of low gears (first and second, or only second gear), “winter mode”;

- L(or number 1 ) - second range of low gears (first gear only).

Automatic transmission mode diagram

Automatic transmission mode diagram There are also additional buttons that characterize the operating modes of the automatic transmission.

ARTICLE VIDEO How does an automatic transmission work? What are all the advantages and delights of driving a car with an automatic transmission, how reliable and durable is the automatic transmission, what can and cannot be done if you have an automatic transmission, and is the automatic transmission really as “dumb” as they say, or can it “do the job”? » the car on the mechanics and leave it far behind? Read in this article!

Automatic transmission device

The automatic transmission consists of several main components:

Arrangement of elements in the automatic transmission box:

Planetary gear system

The heart of the automatic transmission is the planetary mechanism.

The heart of the automatic transmission is the planetary mechanism.

Planetary gears have 3 degrees of freedom. This means that in order to transmit rotation, one of the 3 elements (satellites do not count) must be stopped.

If you do not stop any of the elements, then each will be able to move freely, and in this case there will be no transmission of rotation.

You can brake other elements, as well as swap the entry and exit points, obtaining different gear ratios and reverse directions of rotation.

In this case, the external dimensions of the structure will change slightly. Such properties determined the use of planetary mechanisms in automatic transmissions.

Automatic transmission, short video on the device:

Torque converter

A torque converter is used to transmit torque from the automatic transmission to the engine. In fact, it performs almost the same functions as the clutch in mechanics.

A torque converter is used to transmit torque from the automatic transmission to the engine. In fact, it performs almost the same functions as the clutch in mechanics.

In addition, it can increase torque by reducing the reactor's fluid flow rate.

Operating principle of the torque converter:

The torque converter consists of three main elements.

These are two blades, one on the gearbox side, the other on the engine side. Between them is the so-called reactor. All these three parts are not mechanically connected to each other; they are in a special liquid.

When the blades connected to the engine rotate, torque is transmitted through liquid to the blades connected to the box, and the box begins to work.

The geometric characteristics of the torque converter blades and cross-section are selected in such a way that at idle speed the torque transmitted from the engine is very small and can be countered even by lightly pressing the brake pedal.

However, a slight press on the gas pedal and a slight increase in speed causes a significant increase in the transmitted torque.

This happens because as the engine speed increases, the direction of the fluid flow changes in the direction of increasing pressure on the turbine blades

Torque converters of modern automatic transmissions can increase the torque transmitted from the engine by two to three times. This effect only occurs when the crankshaft rotates significantly faster than the automatic transmission input shaft.

As the car picks up speed, this difference decreases and a moment comes when the input shaft rotates at almost the same speed as the crankshaft, but not exactly, since the transmission of torque from the engine to the automatic transmission is carried out through liquid, i.e. with slippage.

This is part of the explanation why cars with automatic transmission are less economical and dynamic rather than exactly the same ones with manual transmission.

To minimize these losses, torque converters are equipped with locking devices. When the angular speeds of the impeller and turbine are aligned, the locking connects them into a single unit, eliminating slippage.

Clutches are automatically used to connect the elements of the planetary mechanism to the input shaft of the box, and brakes are used to stop it relative to the housing. Both of them are most often multi-disc clutches.

Hydraulic system

The working fluid in the automatic transmission hydraulic system is ATF oil, which provides lubrication, cooling, gear shifting and connection of the transmission to the engine. As a rule, the oil in the box is in the crankcase.

Because The oil volume changes during automatic transmission operation; it is connected to atmospheric air through a dipstick.

As source of pressure in the automatic transmission internal gear pumps are used. The advantage of internal gear pumps is the high pump power, especially at low speeds.